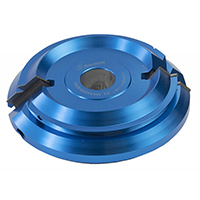

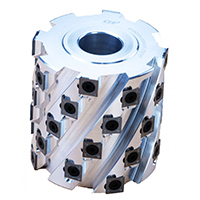

A spiral cutterhead is a valuable accessory for jointers, offering numerous benefits such as improved cutting performance, reduced noise, and extended blade life. It is essential to follow proper maintenance practices and address any potential issues promptly to ensure the longevity and optimal performance of your spiral cutterhead for a Metabo jointer. In this blog, we will provide valuable tips for maintaining and troubleshooting your spiral cutterhead, allowing you to achieve consistent and high-quality results.

· Regular Cleaning:

One of the key maintenance tasks for a spiral cutterhead is regular cleaning for jointers. Chips and debris can accumulate in the cutterhead's spiral design, affecting its cutting efficiency. After each use, remove the cutterhead guard and carefully clean the cutterhead using compressed air or a small brush. Pay special attention to the spaces between the carbide inserts, ensuring all debris is cleared away.

· Inspection and Adjustment:

Regularly inspect the carbide inserts on the spiral cutterhead to ensure they are securely in place and in good condition. Check for any signs of wear or damage, such as chips or dullness. If necessary, replace any worn or damaged inserts with new ones from the manufacturer. Additionally, verify that the inserts are aligned properly and at the correct height for optimal cutting performance.

· Lubrication:

Proper lubrication is crucial for the smooth operation of a spiral cutterhead. Consult the manufacturer's recommendations for the specific lubricant to use. Apply a small amount of lubricant to the bearings or bushings according to the provided instructions. This will help reduce friction and extend the life of the cutterhead.

· Blade Alignment:

If you notice uneven cuts or excessive noise during operation, blade misalignment could be the issue. Check the alignment of the spiral cutterhead blades and adjust if necessary. Most manufacturers provide guidelines for aligning the blades correctly. Follow these instructions carefully to ensure precise and consistent cutting performance.

· Troubleshooting Common Issues:

If you encounter problems such as tear-out, snipe, or inconsistent cutting results, there are a few troubleshooting steps you can take. First, check that the jointer bed is flat and level. Next, inspect the carbide inserts for damage or wear. If necessary, rotate or replace them. Additionally, ensure that the jointer knives are properly set and adjusted. If issues persist, consult the manufacturer or seek guidance from a professional.

Unlock the Potential: High-Quality Spiral Cutterheads for Metabo Jointers at Shear Tak

At Shear Tak, we offer high-quality spiral cutterheads designed specifically for Metabo jointers. Explore our range of spiral cutterheads and experience the difference in performance and longevity. Invest in the maintenance of your spiral cutterhead today and elevate your woodworking projects to new heights. Unlock the full potential of your Metabo jointer with our top-notch spiral cutterheads.