In 1946, Callander Foundry & Manufacturing Co. released a new line of high-quality woodworking tools branded the “Beaver Power Tools”. These durable machines were designed to be used in the typical home shop, providing woodworkers of all skill levels with a smooth machining experience. The company was based in Guelph, Ontario, and spent a large portion of the 20th century developing tools and machinery. The machines’ excellent design and impressive weight made them shock-absorbent and established the significant advantage they brought to modern machining. The Beaver JP-3800 6” Jointer-Planer (pictured below) was especially versatile, consisting of an extending table that could accommodate larger pieces of wood.

With the line of historic tools no longer in circulation, woodworking enthusiasts are seeking new ways to bring value back to the Beaver Power Tools. When approached by the owner of a Beaver JP-3800 6” Jointer-Planer, we at Sheartak were very excited to create a custom spiral cutterhead for the model. The original cutterhead featured in the jointer was far different from the typical cutterhead shape and structure seen today. It included two special Timken bearing cups on the shaft to help fit in the machine sleeves. The cutterhead was designed to fit with durable bearing trunnions, requiring high precision and attention to detail.

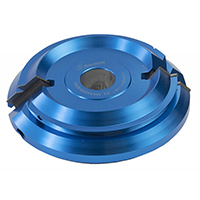

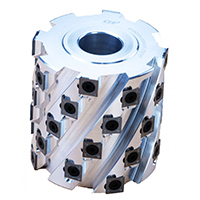

We were glad to present our custom one-of-a-kind spiral cutterhead for the Beaver JP-3800. The 6” Sheartak spiral cutterhead featured 5 spirals with 30 carbide inserts and dramatically improved the finish on wood pieces. The spiral design of the cutterhead decreased the noise created by the machining process due to the constant contact of the knives on the cutting surface. The carbide inserts were easy to remove and replace, providing a quick maintenance/repair process. The small inserts eased the dust extraction procedure, as thinner materials were removed from the surface.

The cutterhead was replaced with the following process:

- Loosen the two set screws on top of the bearing trunnions (pins) with an Allen key.

- Loosen the trunnion adjustment screws with a large flat-headed screwdriver.

- Turn the machine upside down and remove the front trunnion adjustment pin fully with a large flat-headed screwdriver.

- Remove the cutterhead and belt.

- Reverse steps to install the new cutterhead.

We are pleased with the performance of this truly unique spiral cutterhead and urge you to learn more about it at https://www.sheartak.com/spiral-cutterhead/ridgid/spiral-cutterhead-beaver-JP-3800-jointer-planer. We are always searching for new opportunities to honor the various woodworking machines that have been influential across history. The Beaver JP-3800 6” Jointer-Planer is an amazing piece of Canadian heritage, and we look forward to seeing the incredible work that it can achieve with a Sheartak spiral cutterhead.