There are so many tools that you may need, and they are all expensive if you want good quality in your products. But there is actually a way to cut down on the cost of your machines without hindering the quality of your products. First off, old machines don't wear out. Purchasing a used machine or an older model is a great way to save some money. It may not have all the features as new ones, but it still gets the job done.

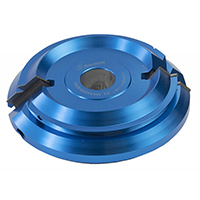

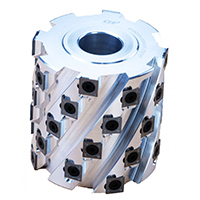

Additionally, making upgrades to your machines can increase the efficiency of your workflow. People can spend hours or even days sanding down a project, and we all know that time is money. By upgrading to a spiral cutterhead, getting the sanding job finished would be quicker than ever.

Another way that the spiral cutter head can save money is by eliminating the hassle of replacing traditional straight-edge knives. Depending on how often you use your machine, you may need to replace straight-edge blades twice a year. This estimate is also assuming that you are lucky and never damage your blade. Chipping your blade is a very common issue, and if ignored, you would have to spend more time sanding the wood down. Otherwise, you would need to replace the whole blade. Each blade can cost up to 20 dollars, and it takes about 10 to 20 minutes to replace. Over the years, this can stack up to a lot of time and money. Consider purchasing a spiral cutterhead since each blade costs 2-5 dollars and can be reused up to 4 times by just rotating the cutting edge 90 degrees. This is a super easy process that should only take you 1 to 2 minutes. A carbide insert from sheartak can last up to 50 times the lifespan of your equipment with high-speed steel blades. In addition, if a blade gets damaged, you only need to fix one small portion rather than replace the whole knife with the traditional type.

In addition, spiral cutterheads offer increased versatility by being designed to handle a wider range of materials such as hardwood, softwood, MDF, plywood, plastics, and composites. Straight knives, on the other hand, may struggle to cut through these materials effectively, leading to reduced efficiency and accuracy, shorter lifespan of the knives, produces rough surfaces and lots of cutting waste. This reduces the need for multiple cutterheads for different projects, ultimately saving money on equipment costs, increasing the machine's flexibility, lowering material costs and higher yields.

In conclusion, if you want to save money and don't know where to start, consider purchasing an older machine and upgrading it with a spiral cutter head. You would be surprised how well your machine works. Trust the long-term investment, and you will save both time and money in your projects.