The main sources of noise generated by machines can be attributed to the following factors:

Vibration: If a machine is not leveled properly, it may vibrate and produce noise.

Motor: Motors that contain gears can generate noise when the gears come into contact with each other.

Moving parts: Machines with moving parts may produce noise if they are not lubricated properly or become worn over time.

Cutting parameters: Increasing the cutting depth, feeding speed of the material or tool, or tool speed can result in higher noise levels.

Material properties: Cutting hard materials is generally louder than cutting soft materials.

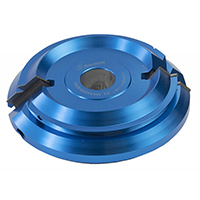

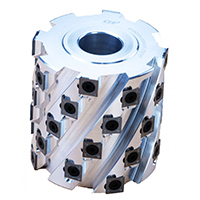

Helical or spiral cutterheads generate noise from three sources:

a) the helical grooves and carbide inserts that move against air during rotation.

b) the blades cutting materials. Compared to traditional cutter heads, helical or spiral cutterheads cut much quieter due to the continuous staggered manner in which the carbide inserts are used.

c) the dynamic balance of the cutterhead.

The operation noise of a planer or jointer is a combination of these factors. Although helical cutterheads can greatly reduce noise, there is no evidence to suggest that they can achieve a 50% reduction.

In contrast to machines, buzzing sounds from insects such as bees, flies, and wasps are primarily caused by the rapid beating of their wings. Helical or spiral cutterheads cannot generate buzzing sounds.