Sometimes the latest and newest technology is not always your best option. In industrial fields, old machines are still trustworthy to use with quality performance. All they need is a little upgrading.

In the woodworking community, many workers choose to purchase second-hand machines. The equipment is all in working condition, and they just cannot be sold as new anymore. This is highly economically beneficial as they will be at a discounted price. New mini handheld planers can be priced at around $200, and 12-inch planers are mostly around $700-800, while used ones are under $500. For example, a biscuit jointer or planer bought new all cost around $200 and up, but a biscuit jointer found on Kijiji is only $50! Especially for new hobbyists or business starters, buying second-hand is a great idea when you are not looking for a specific brand or model. Be prepared to trade some time and energy to keep the money. Lots of research, comparing sellers, and maybe slight repairs will be necessary. It is recommended to look up the machine manual and parts list if the parts are still available for purchase and check common problems of that specific model.

Environmentally speaking, it is more sustainable to choose to retrofit. Often, returned machines get sent straight to the landfill. Machines with parts in good condition that can easily be fixed are getting wasted while more new ones are getting made. Buying second-hand machines can reduce production demand and reduce material wastage.

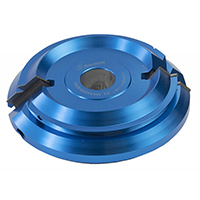

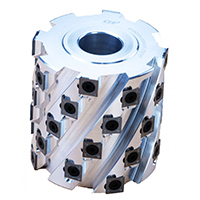

The best way to upgrade an old machine is to replace the cutterhead with a spiral cutterhead. It can alleviate the machine’s performance through substantial noise reduction, no tear-outs even on figured lumber, and sustaining machine lifetime. The staggered cutting breaks up chips for easy material removal, and each carbide blade can be rotated 90 degrees for a brand-new sharp edge. Only replace the blade when all four edges are dull. The clean-up process is also easier, as the clean cutting reduces three-quarters of the sanding work. For some tutorials on the installation process, check out our YouTube channel @Sheartak Tools for various planner upgrades. We also offer cutterheads for more than 800 planers and jointers and all the supplies you’d need to upgrade your machine.